Sobey’s Private Area

[pc-logout-box][pc-login-form]

[pc-logout-box][pc-login-form]

Maximize your most valuable ‘real estate’.

Though some restaurants sell art, sauces and clothes, most foodservice operators only sell the items listed on their menu, making menu space very valuable ‘real estate’. And since operators are trying to maximize every sale from the menu, the profitability of each item must be accurately calculated, constantly updated, and forever analyzed. With a fixed number of guests dining daily, the profit generated per item, or Food Margin, should be the primary consideration when developing a menu.

Traditionally, Food Cost has been the determining factor for menu development. While this method is a great system for managing the efficiency of an operation, controlling waste, over portioning, theft, etc., it does not address the «opportunity» of a menu item. Basing menu decisions solely on Food Cost lends to ‘shopping on price’ rather than ‘shopping on quality’. In other words, purchases are limited to items that achieve a certain food cost while items that potentially contribute higher margins are not considered.

Beef consistently out-performs other proteins when it comes to Food Margin, often despite a higher Food Cost. Because of beef’s perceived value, merchandising quality beef entrées on your menu is a sure way to increase the overall profitability of your operation. Not only will beef contribute to margins, a well-executed beef program will drive traffic to your restaurant, generating increased sales.

The process of merchandising a menu is sometimes referred to as Menu Engineering. This complex analysis looks at each item on a menu and how it contributes to the overall profitability of the menu as a whole. Savvy operators are constantly analyzing and tweaking their menus to generate top dollar. Our Financial Tools for the Meat Professional is a great way to help you engineer your menu.

Determining the cost and margin of a menu item is made relevant to your business when real sales data is collected. Most point-of-sales systems will do this job for you by providing a report listing each menu item and the corresponding number sold. The quantity sold is the relevant number for this comparison, not the sales ($) of each item.

Choose a period to collect data, or take a «snapshot» in time. We recommend a minimum of four weeks of data, though increasing the period provides better representation. Obviously promotions or specials will skew the numbers so try to look at a period that is not influenced by incentives. Also, group the items by category, such as entrée, appetizer, salads, etc. For our examples, we will only be looking at entrées and how they perform against each other.

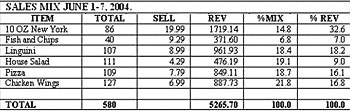

You will notice on the sample report that the New York steak represents only 14.8% of the sales mix but 32.6% of the revenue generated.

Food Margin, unlike Food Cost, measures dollars rather than percentages. After all, you bank dollars and your financial statements are based on dollars. To accurately calculate a plate’s margin, like anything, you will need accurate inputs. This means that you must:

Now you have the two critical numbers needed: Quantity Sold for the period and Food Margin for each item. Now we want to see how each stacks up against the others. Remember, we are comparing similar categories only.

The grid below plots both Food Margin and Quantity Sold. Regardless of the period you chose, all items plotted must be derived from the same period. The «X» (horizontal) axis measures Food Margin, with $0.00 at the bottom and the highest item’s margin on the top. The «Y» (vertical) axis plots quantity sold, with «0 sold» on the bottom and the highest number sold on the top. Where the lines intersect is the mid point for both margin and quantity. Now plot each item using the two axes as a reference.

The items that you plotted on the graph have fallen into one of four quadrants and each tells a story about the performance of that menu item. For reference, we will use the following names to refer to each zone, and to the characteristics of the corresponding menu items too. This is where you take the emotion out of your menu. Forget about what you have offered since you first opened, Grandma’s famous recipe, or the dish that Mrs. Smith asks for once a month. Let the numbers speak for themselves.

The Dogs represent items that have Low Margins and Low Quantity sold. These are the «losers» on your menu and have probably seen their day. These items seldom sell and, when they do, produce small profits.

Recommendation: Remove most dogs from the menu as they are taking up valuable space. It may make sense to keep some of them where ingredients are shared with other item, In this case, the dogs should be «hidden», or downplayed on the menu.

The Plow Horses represent items that have Low Margins but a High Quantity sold. You can always count on Plow Horses to be popular dishes. Though they are not the highest profit generators, Plow Horses keep on selling.

Recommendation: Plow Horses are ideal candidates for modest price increases. Of course a slight increase in price may decrease quantity sold so the overall balance needs to be considered.

Puzzles are those items that have High Margins but have Low Quantity sold. You want to sell more Puzzles so added attention needed.

Recommendation: Reposition Puzzles on the menu, enhance them with colour, graphics, photos, etc. Draw your guests to the Puzzles through menu enhancement, promotion and staff knowledge.

Stars are the winners on the menu: High Margins and High Quantity sold. You want everything on your menu to move toward the Star quadrant. The nature of the four box analysis will not allow everything to be a star, though that should be the direction of the menu.

Recommendation: Don’t mess with success. Stars need to be the center of the menu, enjoying prime marketing and be subjected to increased controls. Since you sell a lot of Stars, something like over-portioning by 1 oz on a Star can have a dramatic impact on your margins.

Generally speaking, following the above recommendations will have a positive impact on the profitability of your menu. There is some consideration needed on where in a grid a particular item falls. For example, increasing the selling price of a Plow Horse that plots very close to the Star quadrant will be less affected in Quantity Sold than the same increase on an item further from the Star quadrant.

The science portion of the menu engineering involves the calculations and plotting. The numbers and implications this exercise will provide will lend some valuable insights to your menu opportunities. While we have outlined the theory of menu analysis, taking this information and applying it to a successful menu redesign may require professional services to make the most of it.

In this section, we will review some key financial tools and concepts you will need as you round out your beef knowledge. Your understanding of the financial contributions of various menu items will greatly impact the overall profitability of the operation.

Food Cost measures the cost ingredients as a percentage of the selling price of the dish. It is a great system to help monitor the efficiency of a kitchen but not necessarily the best for developing a profitable menu. To calculate the food cost of an item, divide the cost of the item by its selling price to get the food cost percentage:

The above example illustrates costing on one item. In order to calculate the food cost for an entire menu and use it effectively as a tool for monitoring efficiency, inventories are necessary – usually weekly or monthly. This process involves an Opening Inventory, adding Purchases, less a Closing Inventory. The derived number is the Usage, measured in dollars. Dividing the total Usage by the Total Sales will produce the Actual Food Cost.

The above example illustrates costing on one item. In order to calculate the food cost for an entire menu and use it effectively as a tool for monitoring efficiency, inventories are necessary – usually weekly or monthly. This process involves an Opening Inventory, adding Purchases, less a Closing Inventory. The derived number is the Usage, measured in dollars. Dividing the total Usage by the Total Sales will produce the Actual Food Cost.

In order for food costing to be an effective tool, you need to measure the Actual Food Cost against the Theoretical Food Cost. The difference between the two numbers is your inefficiency (poor product rotation, returns, theft and over portioning). Calculating Theoretical Food Costs requires a product sales mix – a listing of quantity sold, by menu item, for the given period. You already know the Theoretical Cost of each item (what it should cost), but because different items have different costs, the overall menu cost will change day-to-day based on different items sold, or menu mix.

In the example below, the total cost of the menu (assuming there were only 3 items) was $94.00. If the total sales for the week were $300.00, the Theoretical Menu Cost for that week would be 31.3%.

ITEM |

COST |

QTY SOLD |

TOTAL |

|---|---|---|---|

|

|

|||

| Steak Sandwich | $6.45 | 5 | $32.27 |

| 8 oz Sirloin | $9.76 | 4 | $39.02 |

| 10 oz New York | $11.36 | 2 | $22.71 |

|

|

|||

TOTAL |

$94.00 |

||

Subtracting the Actual Food Cost from the Theoretical Food Cost will provide the amount of Waste (inefficiency) for the period in a percentage. If you multiply that by the sales, you will know how many dollars were wasted for that period. This system is great to zero in on problem areas in the kitchen and help ensure that the planned cost of the item is the real cost.

Contribution Margin, on the other hand, is the amount of dollars a particular item contributes to the bottom line profitability of a restaurant. Since the restaurant is in business to bank dollars, not food cost percentages, this is a more logical method to build a profitable menu. To calculate the contribution of an item, simply subtract the Item Cost from the Selling Price. This will produce the profit every time this item is sold.

The following example compares the two methods on a typical menu decision. The next time you believe that the beef you are buying is too expensive, or that upgrading the quality is not financially feasible, work through this exercise. Guests will pay more for beef on a menu over other proteins as it is perceived to be of higher value. The ceiling price for a chicken sandwich, in this example, is considerably lower.

7 oz Steak Sandwich |

6 oz Chicken Sandwich |

||

|---|---|---|---|

|

|

|||

| Cost of Plate | $3.40 | Cost of Plate | $2.27 |

| Selling Price | $9.50 | Selling Price | $7.50 |

| Food Cost | 35.7% | Food Cost | 28.5% |

|

|

|||

| Contribution | $6.10 | Contribution | $5.23 |

|

|

|||

| Sell 50 steaks, the gross profit is $305.00 |

Sell 50 chicken, the gross profit is $261.50 |

||

The gross profit on the steak was $43.50 more for the same amount of labour. |

|||

Calculating the yield of portioned beef will give a realistic comparison of whole muscle versus pre-portioned product. Just because the price per pound is usually lower on whole muscle cuts, the useable product derived from steaking in-house may not turn out to be more profitable. On the other hand, at certain times of the year and with specific cuts, whole muscle may be better financially.

Understanding yield and being able to work through a yield test has several advantages:

First, determine your costs and identify the items being tested. Identify all first and secondary portion cuts, any bone, trim and fat and record their weights. Calculate the weight percentages of all items and record them. How many people are being fed? What is the price paid for your beef? What is the serving size? Remember that this is a very simple yield test and you are encouraged to spend some time learning the Financial Tools for the Meat Professional, which follows.

The Foodservice Financial Tools are designed for operators who are serious about understanding the financial performance of beef on their menu. The use of this program requires Microsoft Excel to be installed on your computer – please follow the instructions below to use.

Appropriate selection and purchasing of raw materials is an important first step. The Yield Test Spreadsheet includes the ability to:

Appropriate selection and purchasing of raw materials is an important first step. The Yield Test Spreadsheet includes the ability to:

The quality of meat products is significantly impacted by preparation methods. Use the yield test spreadsheet to:

The Yield Test Spreadsheet enables the user to track yields as well as associated costs and revenues from beef, veal and other common meat and poultry products. The Compare Yield Test Spreadsheet permits up to five yield tests to be compared simultaneously. The financial tools include printable forms to make yield test data capture easier and more accurate. Reports can also be produced to document yield test findings and comparisons.

At foodservice, the meat comes on a plate. The yield test spreadsheet helps you put it all together:

At foodservice, the meat comes on a plate. The yield test spreadsheet helps you put it all together:

Sometimes the best way to make a financial decision is to make comparisons:

6 Steps to Success with Beef

Even though the food cost is often higher on beef dishes, the perceived value of beef means you can ask higher selling prices, which means more dollars to your bottom line. So does it make sense to sell as much beef as you can, despite higher food costs? Most definitely!

Perceived Value Pricing means setting the price of menu items at a level that offers good return for the operator while still being able to sell the item in reasonable quantities. «The lowest price in town» is never a good long-term success strategy. You need to understand how much your customer is willing to pay for the quality and service you provide. The exact selling price you charge will depend on a number of factors including your concept, your customer demographics, your competition, and the day-part the meal is being served. This varies for everyone but there are some specific opportunities that operators have in common to maximize «Perceived Value» pricing.

How you merchandise your menu has an impact on its perceived value, but each meal still has to consistently deliver quality and a great eating experience. When it comes to beef you get what you pay for. Because beef pricing is generally dictated by supply and demand dynamics there are seldom any deals on beef – especially at foodservice. Most guests are looking for a tender, juicy and flavourful steak, not the cheapest steak available. Work with your supplier to ensure that your beef specifications include the following measurable quality attributes:

Highly marbled beef – marbling is the small flecks of intramuscular fat in the lean of the muscle, which contributes to juiciness and flavour. Marbling is measured by the grade (A, AA, AAA, and Prime) and its determination is a function of the Canadian Beef Grading Agency (CBGA). MORE

Well-aged beef -the term «aging» refers to the length of time beef is stored under controlled conditions while naturally occurring enzymes within the meat slowly break down some of the connective tissues that contribute to toughness. This is an important component to a great steak. The aging process usually occurs at the distributor level and is primarily «wet aged» in cryovac. For most beef cuts 21 days aging is optimal. MORE

Chose the right cut of beef for your application. Price doesn’t always dictate quality and won’t necessarily mean a better eating experience. How the product is cooked impacts greatly on the finished steak or roast. Familiarize yourself with the various cooking techniques and what method each cut performs best under. It is recommended that you work with your beef supplier to determine which cuts will work best for your operation.

Photo of the Cooked to Perfection bookletProper receiving, handling, storage and food safety techniques play a big part in the quality of the finished product. For example, if frozen beef is not properly tempered (defrosted), quality will deteriorate and may also introduce unnecessary food safety risks to the product. Think of your decision to purchase high quality beef as only the first step to deliver a quality beef program in your foodservice operation.

Steak doneness is one of the most important factors in determining a quality steak. In fact, recent surveys have shown that 50% of customers say getting their steak done the way they like it is the biggest determining factor to a great steak experience. Getting steak doneness right is a team effort, starting at the table. Remember, one person’s idea of «medium-rare» may not be everyone’s.

With your decision to purchase and promote a high quality beef program on your menu you must take every opportunity to communicate this quality to your guests. Once they appreciate that the quality of your beef means a more enjoyable eating experience, they will understand the increased menu price.

When talking quality on your menu, point of sale materials or through your staff make sure you relay the quality factors that your guests understand and that influence the eating experience. For example, «We select only Canada AAA beef to ensure a juicy and flavourful steak every time» or «Our beef is aged a minimum of 21 days for maximum tenderness».

With your beef dishes generating some of the highest revenue on the menu your time is better spent communicating the quality of these items rather than items on your menu like pasta dishes which historically produce less food margin. Steaks and roasts are not a «hard sell» to guests, they just want to know that they are going to receive value and have a great experience.

There are training materials and promotional resources available to you as a supporter of Canadian beef. Improving your overall beef knowledge will go a long way in determining the success of your beef program. Become an expert in all aspects of the beef in your operation: the source, quality specifications, how to handle, cook and cut it, and how to merchandise for best results.

There is a lot of misinformation about what makes a good steak. Many consumers believe what they’re told by so-called experts, whether right or wrong. And to most restaurant patrons, the staff and management are experts on the items sold on the menu but remember, your guests were someone else’s guests before and who knows what they were told about quality beef. Your job is to clear up the «smoke and mirrors» and teach your guests what really makes a great steak.

Communicating your beef quality and teaching your guests the «hows» and «whys» of quality beef will benefit you very quickly. Assuming their steak is tender, juicy, flavourful and cooked to perfection, and the knowledge of what contributes to steak quality, will undoubtedly have your guests searching the town for similar quality steaks. You will have set a new standard of excellence with your guests and now they know where to go to meet their expectations.

Your guests will become your best form of marketing – knowing what makes a great steak and where to find it. There is one school of thought that says all recipe information and kitchen operations are closely guarded secrets but that approach is a thing of the past. With the popularity of open-style kitchens, the promotion of fresh and quality ingredients, and the increase in restaurant-style cooking shows, clearly your guests want to know what they are eating.

If you buy quality beef and consistently deliver quality steaks and roasts, flaunt it at every opportunity. This will enhance the perceived value of the menu thus generate added revenue and grow your business.

Ensure your staff has the necessary knowledge and tools to make your beef program succeed. Just like the point of sale material on the table, if your staff cannot speak to the quality of your beef program and make informed recommendations to your guest they just become part of the furniture.

Take every opportunity to pass on your knowledge so that serving staff can effectively merchandise the menu to the guest. There are number of things you need to keep in mind when training wait staff.

In most Foodservice operations, you have a number of opportunities to influence the guests’ decision around menu selection. The restaurateur’s objective in merchandising should be to:

Taking full advantage of all merchandising opportunities will contribute to a successful beef program.

The lobby is often the first opportunity to influence guests’ purchasing decisions. Tasteful quality messages such as: «We serve great Canadian ‘AAA’ beef!» demonstrate that the operation cares about the ingredients they purchase. This works well for both steak houses and traditional restaurants alike.

A well-written menu that emphasizes quality is part of every successful steak program. A well-designed menu will not only look at where items are placed, but also how the items are communicated. Where items are placed and how a menu is read is referred to as menu engineering. Highlighting beef features with different colours, photography, larger text, etc., will draw the guest’s eye directly to that area. Once you have the guest’s attention, it is very beneficial to use the menu to drive home the restaurant’s demand for quality offerings. Obviously not all operators will purchase ‘AAA’ beef, but all Canadian beef is high quality and can be effectively marketed as a premium item. Some examples of impact statements are:

When it comes to beef, «quality» includes those attributes which most affect the dining experience: grade, age, cut, and safety.

Whenever possible, the menu and staff should communicate these quality attributes in terms the restaurant guests will understand. There is a relationship between price and quality; consumers do not want a cheap steak – they want a great steak. Other descriptive and appetizing words like seared, hand carved, succulent, fire roasted, herb crusted, pan roasted, oven roasted, spice crusted, glazed, sizzling and well-marbled add to the excitement.

The table is a well used but often misused opportunity for merchandising. Table tents can inform your guests directly about specials or feature items even before your wait staff provides information on what is new or special. Most restaurants are busy places with lots of distractions. Some key things to keep in mind when merchandising on the table are:

The 3 C’s of Food Safety

Receiving Procedures

Product Rotation

Photo of commercial facilitiesThe 3 C’s of food safety are simple guidelines that all foodservice operators should practice. Safe handling procedures will help minimize potential risk and ensure that safe food leaves your kitchen at all times.

Cold Chain Management is the process of maintaining critical food temperatures along the supply chain, from manufacturing to serving. Maintaining the cold chain temperature limits the growth of harmful pathogens that could lead to a food-borne illness and also prevents excessive purge from the beef that reduces yield and product quality. Therefore, when preparing beef, it is important not to leave multiple cases of beef out at room temperature awaiting cutting. Similarly, never leave cases of product at the back door after delivery, waiting for a staff member to put them away.

Tips on CleanlinessBeef, like other proteins, fruits and vegetables, can harbour harmful bacteria. Providing a sanitized environment for storage, handling and preparation helps keep beef and other products safe. Preventing cross-contamination when handling and storing beef must be a priority for all food handlers. When beef is stored, ensure raw meat is covered and placed on lower shelves — this will prevent juices from coming in contact with cooked items on upper shelves. When cutting and preparing beef, use a clean workstation with cutting boards assigned for different classes of food (chicken, beef, fish, produce, etc.) and sanitize them between uses.

Similar to other meat products, beef will dry out if not covered during storage and handling, reducing the quality. Keeping beef covered also prevents cross-contamination to or from other products. Cooked beef should also be covered to keep it safe.

Download «A Design for Safety» for more information about safety (PDF)

On initially opening a vacuum bag, an off door may be detected. This is not a sign the meat is bad, rather it is the lactic acid which develops in the bag where there is no oxygen. The door should dissipate within 10-15 minutes after being exposed to oxygen.

Receiving scales are good to have near the back door for spot checking deliveries.

Foodservice operators’ contribution to a safe food supply begins at the receiving door. Procedures should be in place to:

The boxes of beef should be intact and clean and the temperature should be probed. If frozen, make sure the beef is completely frozen. With fresh product, look for «leakers» which are when the vacuum bags did not seal properly or the seal was broken at some point. Leakers will often contain sour product which is noticeable upon opening. It is best to make sure leakers are not used and are returned immediately so the cause of the leak can be determined. Customers should refuse any product that is too warm or not completely frozen, and a notation of the problem should be made for follow-up with the distributor and manufacturer. Leakers are easily identified as the bag is loose around the beef and the cuts move freely in the bag. A good vacuum will be very tight around the beef cut.

The receiver should compare the box labels against the invoice to verify that the grade matches (A, AA, AAA, Prime), and the weights coincide. Any discrepancies should be noted and signed by the driver. The product specifications should be clearly identified, «0X1 STRIPLOINS», for example. Receivers and other staff should know how to identify beef specifications in order to determine accuracy as not all labels will be as clear as the one below. This typical packer label would appear on original packer boxes but if the product has been further processed (steaked, cooked, marinated, etc.), a different label may appear.

The receiver should compare the box labels against the invoice to verify that the grade matches (A, AA, AAA, Prime), and the weights coincide. Any discrepancies should be noted and signed by the driver. The product specifications should be clearly identified, «0X1 STRIPLOINS», for example. Receivers and other staff should know how to identify beef specifications in order to determine accuracy as not all labels will be as clear as the one below. This typical packer label would appear on original packer boxes but if the product has been further processed (steaked, cooked, marinated, etc.), a different label may appear.

The packing date, or the date the product was processed, should also be marked on the label. Counting back from this date will provide you the number of aging days. This number should be consistent with your beef specifications or your contracted aging requirement, if applicable.

Download the «Labelling Fact Sheet» for more information about labelling (PDF)

There are a number of labeling guidelines you should be familiar with. Monitoring label compliance is a function of the Canada Food Inspection Agency (CFIA).

It is necessary in a supply-demand market that products be traded fairly. Customers must get what they pay for and their guests must be served the entrées as advertised on the menu. If you suspect fraudulent practices as it relates to the representation of beef items, you are encouraged to contact your local branch of the Canadian Food Inspection Agency. You can also view the meat regulations at laws.justice.gc.ca.

It is essential that proper storage and rotation is practised within your operation. Managing the product in the kitchen will ensure fewer losses on spoiled products and higher yields. Review FIFO (First In – First Out) procedures and consider implementing a «day dot program» to manage fresh inventories effectively. Assigning different coloured dot stickers for each day of the week will help ensure you are using the oldest product first.

If storing beef under refrigeration, remember that temperatures in walk-in coolers can vary a great deal due to the opening and closing of the doors. Beef is best stored in the coldest spot – the bottom shelf of the back corner – furthest from the door. If storing frozen beef, ensure temperatures of -10°C to -18°C, or less, and keep the product in its original packaging to help minimize freezer burn. The following factors affect the storage life of beef:

Packaging |

Refrigerator(-2°C to 2°C) |

Freezer(-10°C to -18°C or less) |

|---|---|---|

|

|

||

| Vacuum Packed Cuts | 16+ days* | 6-12 months |

| Opened Vacuum Package | 2 days | After rewrapping: 3-6 months |

|

|

||

* Storage time under refrigeration depends on the age of the product when received and whether it is bone-in or boneless |

||

Many operators will purchase fresh beef and then freeze it themselves. Although this is a safe practice, it defeats the purpose of buying fresh beef. The operator will experience a higher degree of shrinkage from purge as the freezing facilities in most operations cannot duplicate the results of those at manufacturers’ facilities. Beef manufacturers use cryogenic freezer tunnels, which use liquid nitrogen at very cold temperatures resulting in a very quick-freeze. If the operator buys fresh beef and then freezes it, it may be more cost effective to buy frozen beef and to place emphasis on a well-planned tempering program.

There are a number of myths about frozen beef that require clarification. When handled correctly, frozen beef will usually produce the same eating quality of fresh beef.

If purchasing frozen beef, whole-muscle or portioned product, proper thawing is key to maintaining the beef quality.

Always

Thaw beef under refrigerated conditions whenever possible. For steaks, place packages on a baker’s sheet to allow quicker thaw and with larger whole-muscle cuts, allow sufficient time to completely thaw. A roast with a frozen center will take longer to cook and result in inconsistent doneness levels. If pressed for time, place steaks in a bus bin in the sink under cold running water.

Never

Use a microwave to thaw steaks as the meat will toughen and partially cook. Use hot water baths as steaks will cook and juices will leach from meat tissue. Thaw cuts at room temperature. In addition to being a food safety hazard, thawing at room temperature draws moisture out of beef creating a dryer finished product.

As beef is packaged in the oxygen-free environment of the cryovac package, it will tend to be a deep red, purplish colour. Once the package is opened, the familiar red colour will bloom after 15-30 minutes of exposure to oxygen.

Frozen beef does not retain the same quality as fresh beef.

If beef is properly aged, frozen quickly (i.e. cryogenically), and thawed slowly under refrigeration, the taste, juiciness and tenderness will rarely be affected. The only measurable difference is that there may be some additional purge with frozen beef.

Frozen beef is old.

There are some who believe that frozen beef is a product that is old and has been frozen for excessive periods of time. Distributors make decisions to freeze beef based not only on the age of the product, but also on market conditions and purchasing opportunities. If packers need to quickly sell particular cuts, they may offer a discount which the distributor takes advantage of. Once the designated age is reached, only then is the product frozen.

Frozen beef has no age.

The majority of beef that is frozen is usually fully aged since the aging process stops once the beef is frozen. When the beef thaws, the aging process will not restart.

[presentation id=»5291″/]